-

Rack and Pinion Precision Machine Tool Drive Systems

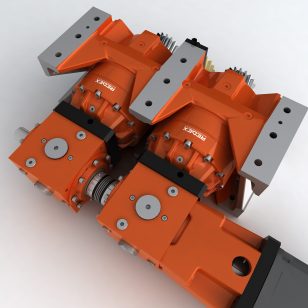

DRP+ the integrated concept

overview

Dedicated to racks & pinions drive applications, the DRP+ design is based on the association of two top quality planetary reducers, mounted in parallel on an extra high stiffness universal frame.

When choosing the mechanical preload solution, the DRP+ become aDualDRIVE unit, which achieve the true backlash free feature by torsionally winding one pinion against the other through the rack. Immediate benefits are to need only one motor, and to dramatically simplify the motor control.

When choosing the Electrical preload solution, the DRP+ is used as a TwinDRIVEunit, where the backlash is cancelled by the opposite torque balance between the two pinions, according with the two motors and drives remote control.

features

- Low inertia driving system.

- 6 Sizes. Reduction ratio : 21 to 91.

- Acceleration up to : 25 m/s2.

- Nominal tangent load (V2=60m/min) : up to 108 000 N.

- Max axis weight (for just one Dual Drive) : up to 62 000 kg.

- Max linear speed : up to 78 m/min

- Backlash free by design

Some Pictures

-

Modular Rack and Pinion Precision Drive Solutions

KRP+ Single, Twin or DualDRIVE

overview

Dedicated to racks & pinions drive applications, the KRP+ design is based either on the use of one single unit or on the association of two top quality planetary reducers, mounted in parallel on the machine main frame.

When used as a SingleDRIVE, the KRP+ gives the benefit of an ultra high stiffness feed gearbox, dedicated to high performances rack & pinions drive systems.

When choosing the mechanical preload solution, the KRP+ become aDualDRIVE unit, which achieve the true backlash free feature by torsionally winding one pinion against the other through the rack. Immediate benefits are to need only one motor, and to dramatically simplify the motor control.

When choosing the Electrical preload solution, the KRP+ is used as a TwinDRIVEunit, where the backlash is cancelled by the opposite torque balance between the two pinions, according with the two motors and drives remote control.

features

- Low inertia driving system. 6 Sizes.

- Reduction ratio : 21 to 91.

- Acceleration up to : 25 m/s2.

- Nominal tangent load (V2=60m/min) : up to 108 000 N.

- Max axis weight : up to 62 000 kg.

- Max linear speed : up to 78 m/min

KRP In Motion

-

Rack and Pinion Blockbuster Drive Systems Linear and Rotary Drive

Turnkey high class planetary Servo-Gearhead

overview

Turnkey high class planetary Servo-Gearhead, dedicated to Rack & Pinion applications

The new benchmark for electrical preload on demanding machine tool applications! KRPX is the new version of REDEX ANDANTEX rack & pinion high-tech planetary reducers, offering cost effective, easy to implement and high performing solutions for moving column or gantry machine types as well as many other applications.

The KRPX housing is made of high quality spheroidal graphite cast iron. Its structure has been optimised with FEM analysis methods to avoid deflection during acceleration. Connection to the machine is made by oversized screws therefore ensuring a solid connection with the machine frame. This allows the KRPX housings to be considered an integrated part of the machine main frame.

The output pinions are machined to the same diameter as the shafts, allowing the best possible balance between transmissible torque and rigidity at the rack. In addition, output bearing consists of two preloaded and substantially oversized angular contact roller bearings.

features

This exclusive design offers exceptional compound stiffness which allows to dramatically decrease the radial bending (up to 60% of the overall distortion) and to increase the natural frequencies of the global Racks & Pinions drive systems.

Designed as a combination of two high-tech planetary reducers, KRPX allows perfect mounting on both sides of the machine frame and enables true zero backlash when coupled with an electrical preload system.

Available in 3 standard universal sizes (2, 3 and 4) KRPX is very compact, a definitive advantage for helping implementation with respective pinion height not higher than 104, 127 and 148 mm.

View in 3D

https://sketchfab.com/models/c429da956e55441fae861e5ed90ee027

-

High Strength Servo Planetary Precision Gearboxes

SRP : an integrated concept

overview

SRP is not one more simple planetary gearbox but a true integrated concept, including several functions combined together to offer a complete sub-assembly to the most demanding machines.

Featuring :

- A heavy duty output oversized tapered bearings assembly

- A high-tech planetary gear train, based on well know REDEX’s differential know-how

- A universal range of servomotor interfaces

- A high quality bevel gear box (option)

features

SRP is the ultimate high-tech servo-reducer, especially dedicated to technical offices looking at the same time for :

- Superior torsional stiffness

- Ultra high radial stiffness and Tilting moment

- High input speed

- Superior acceleration and rated output torque

SRP versatile design allows machine designers to always find the exact solution, according to its very large range of sizes and additional options

- 5 different sizes – 8 different ratios

- Two level of accuracy (1’ or 3’ backlash)

- with right angle motor mounting versions available on each size

- Package solution rack + pinion + reducer, available for each sizes, with two different standard output gears for each size